Protection of concrete from destruction in the street

On how strong and durable will beconcrete structures, can affect the quality and degree of waterproofing before construction begins. To exclude the entry into the material structure of substances that will affect destructively, only well-selected waterproofing systems are capable of. They extend the life of the concrete structure and reduce the cost of restoration, as well as maintenance.

Necessity of protection

Protection of concrete from destruction in the street is necessaryfor the reason that the described material, although it is very strong, but in the process of operation is constantly exposed to destructive factors, among them precipitation, chemical reagents, and industrial gases.

Sometimes concrete is constantly in contact with water, forits protection in this case, materials are used that provide high waterproofing and resistance to chemical and abrasive loads. In this case we are talking about concrete tanks, in which the depth of corrosion damage can reach 50 cm. If not protect the material, then in time it can simply turn into dust.

Varieties of materials for protection

To protect concrete on the street usedmaterials, excluding the impact of moisture, corrosion, as well as increasing strength. This is due to hydrophobic substances, which are applied by the impregnation method. This allows you to reduce the angle of wetting, because the concrete is protected by a silicon-containing compound. The advantage of this approach is its durability and water resistance, as well as its strength. Such substances are enamels, which, under the influence of alkalis, become soluble and lose hydrophobic properties.

Protection of concrete from destruction can beis carried out by a waterproof film. A layer of various resins, for example, polyvinylchloride or polyurethane, is formed on the surface. The disadvantage of the method is low vapor permeability.

If the coating is for a long timewill affect the vapor, it will break up and collapse. In order to eliminate these drawbacks, it is necessary to combine the protective layer and impregnation, but the composition should be created on the same basis. It is important to use alkali-resistant film, whereas the protective layer should have an increased vapor permeability.

Protection against destruction

Considering the means for protecting concrete, youshould identify ways that would prevent the destruction of the material. To such means of protection can be attributed antifungal and antiseptic, as well as paint and varnish materials and impregnations. To protect the structure from destruction, it is possible to apply anticorrosion coating, insulation and impregnation.

Corrosion protection

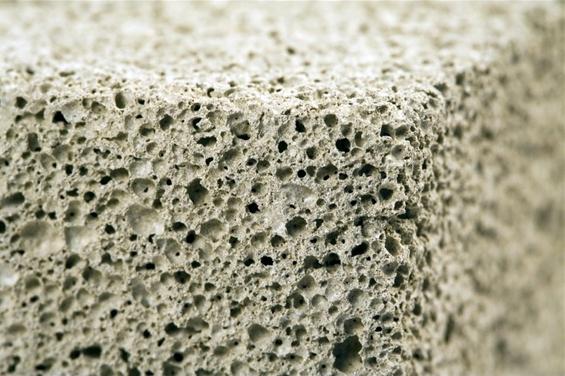

The development of corrosion is due to porosityconcrete. This suggests that it is important to limit the construction from contact with moisture and to eliminate the effects of precipitation. If this can not be avoided, the concrete should be made with increased density, so that the structure is free of pores.

Sometimes a protective coating is applied to the material withhydrophobizing characteristics. The protection of concrete from water by hydrophobizing is the best option to prevent corrosion. The material will repel water and maintain the porosity of the structure, and it will be possible to operate the structure over a wide temperature range from -40 to +50 ° C.

Hydrophobization for anticorrosive protectionis performed in several stages. Additives are added to the cement to increase the density and regulate the porosity. In the next stage, antifungal materials are used, as impregnations for compacting the structure act. To avoid exposure to moisture, paintwork materials are used. To prevent corrosion, carbon fiber tapes should be used. They are excellent for those areas where the metal component of the structure rusted.

Protection against moisture

Concrete protection was previously carried out withusing dry cement mixtures, synthetic sheets and gaskets, as well as roofing material. This is not enough for full protection against water. To solve the problem, the concrete surface must be treated with a liquid with hydrophobic ability. The coating will fill cracks and pores, provide durability and reliable protection.

Protection of concrete from moisture is carried out bya certain algorithm. At the first stage, the finished dry layer must be protected with a sheet of roofing material or waterproof building material. With the help of bitumen emulsion, the seams between sheets are processed. A water-repellent coating, paint or varnish is applied from above.

Use of an anchor sheet

Today concrete is increasingly used to protect concretepolymer sheet, which is located on the surface in staggered order. It is made of high-density polyethylene, abbreviated HDPE. Concrete protection sheet is used for monolithic and prefabricated reinforced concrete objects. Its attachment has a large number of fixation points, which provides a reliable connection or adhesion to concrete or mortar.

The shape of the anchors is formed by extrusion atproduction, which guarantees high strength of fastening. Even with strong fluctuations in temperature and pressure, the optimal distribution of stresses ensures the preservation of the structure of the material, because the force of impact can be caused by groundwater. Anchor sheet for the protection of concrete solves many problems. It creates a barrier to damage to the material by abrasive particles and chemicals.

The layer acts as an infiltrate, excludes corrosionconcrete and protects the material from mechanical damage, which can be caused by humidity, soil vibration, and also by the action of plant roots. Anchor sheet can be installed on the surface in new construction or for the rehabilitation of existing structures. Reconstruction of finished structures eliminates corrosive wear and restores the lost load-bearing capacity. Polymer sheet compensates for abrasive wear and eliminates further destruction.

Installing an anchor plate

If you plan to protect concretean anchor sheet, it is necessary to familiarize yourself with the features of its installation. At the first stage, the material is cut to the size and shape of the surface to be protected. Cloth is attached with an indent from the edge on a removable formwork or by induction welding using mounting discs.

In the space between the polymer sheet andThe protected surface is filled with a concrete mixture, which allows the anchoring of the anchorage. By means of extrusion welding joints between anchor sheets are welded. The resulting seam has a 97% strength of the base material and helps to create a sealed casing.

Using the composition BBM-M

If you are thinking about the question of whatcover concrete on the street for protection, then as an example you can consider the composition of the brand BBM-M. The substance is applied by air spraying, and for brushing the surface, brushes and rollers are used. The thickness of the coating and the depth of impregnation are corrected by the distance of the sprayer from the surface to be treated.

When choosing a spray gun, you should preferdevice that is capable of producing 2 atm. Removing from the concrete base is necessary for 30-50 cm. The recommended coating thickness is 100 microns. If you plan to impregnate the concrete, the thickness of the applied layer is 3 cm. Before forming each subsequent layer, do not wait for the previous one to dry. The described materials are made from domestic polymers, and are inexpensive, because in the basis of undefined raw materials.

Foundation protection

If you need protectionconcrete in the foundation of the house, then it is possible to use the coating of the side surfaces with used engine oil and polyethylene film. The base can be protected by a layer of soil laid along the perimeter. In addition, foam, clay or slag can be used. This allows to reduce the depth of freezing of the ground and eliminate or reduce the impact of negative factors on concrete.

Comprehensive protection against aggressive influences and moisture

In order to achieve a better effect, you canresort to the use of several technologies. To do this, primary protection is used, in which the closing of the cement mortar is accompanied by the addition of chemical modifiers and additives.

To block cracks, you should usesulfate substances, they help against corrosion and provide strength and durability. Secondary protection consists in applying mastics, impregnations, solutions and biocides. An additional measure will be a protective finish, which involves plastering, installing a layer of thermal insulation and installing hinged ventilated facades.

Finally

Concrete is a very strong material thatIt is famous for its longevity, but it is based on a lot of pores, through which moisture inevitably penetrates. When it freezes and crystallizes, it begins to increase in volume, which negatively affects the integrity of the material. But such an impact is not the only thing that can destroy concrete.

To prevent dusting and further lossstrength, it is necessary to protect the structure by adding special solutions to the composition of the solution, which reduce the porosity. During the operation phase, the surface can be protected with mastics and impregnations, which create a kind of barrier in the way of moisture.

</ p>>